08454-235236

give me a call

In optimizing the design of an Industrial Evaporator, another important consideration is the steam economy (kg of liquid evaporated per kilogram of steam used). The best way to achieve high economies is to use a multi effect evaporator, whereby the vapor from one effect – is used to heat the fed in the next effect, where boiling occurs at lower pressure. Thermo-compression of the vapor, whereby the vapor will condense at a temperature high enough to be reused for the next effect through compression, will also increase efficiency.

S.No |

Parameters |

Falling Film |

Forced Circulation |

|---|---|---|---|

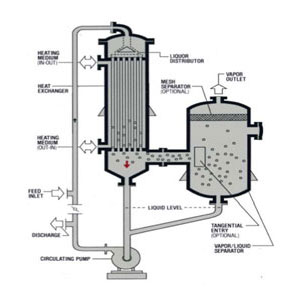

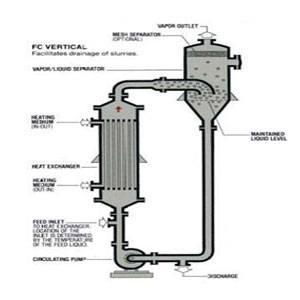

| 1 | Description | In the falling film type the liquid is fed at the top of the long tubes and allowed to fall down the walls as a films. Evaporation occurs on the surface of the highly turbulent film and not on the tube surface. Vapor and liquid are usually separated at the bottom of the tubes. | Evaporators in which circulation is maintained, regardless of evaporation rate or heat duty, by pumping the liquid through the heating element with relatively low evaporation per pass are suitable for a wide variety of applications. The majority of applications are designed such that vaporization does not occur in the tubes. Instead, the process liquid is recirculated by pumping, heated under pressure to prevent boiling, and subsequently flashed to obtain the required vaporization. These are therefore suited for vacuum operation. This type of evaporator is often called the submerged-tube type because the heating element is placed below the liquid level and use the resulting hydrostatic head to prevent boiling. |

| 2 | Nature of feed | Low TDS, Heat Sensitive products like milk, fruit juices, low viscous fluid, pharmaceuticals. | High TDS, Industrial effluent, scale forming liquid, corrosive, medium viscous. |

| 3 | Pressure drop | Low | High |

| 4 | Boiling Point Rise | Minimum | Maximum |

| 5 | Temperature difference | Low | High |

| 6 | Heat Transfer Rate | High at low Dt | Low |

| 7 | Residance Time | Low - (Advantage for heat sensitive product) | High |

| 8 | Issues | The main problem associated with falling film units is the need to distribute the liquid evenly to all tubes. All tubes must be wetted uniformly and this may require recirculation of the liquid unless the ratio of feed to evaporation is relatively high. Recirculation can only be accomplished by pumping. Distribution can be achieved with distributors for individual tubes, with orifice plates above the tubes and tubesheet, or by spraying. Updraft operation complicates the liquid distribution. | high cost; relatively high residence time; and necessary pumps with associated maintenance and operating costs.The pump should operate at its design level. If it develops excessive head, it will handle more volume at a lower head. At the new operating point, the required NPSH may be more than is available, and cavitation will occur in the pump. If insufficient head is provided, the velocities may not be sufficiently high to prevent fouling; lower heat transfer rates may result; or the fluid may boil in the heating element with subsequent fouling or decomposition. |

| 9 | Capex | Less expensive | More Expensive |

| 10 | Opex | Low | High |

| 11 | Pump Flow rates | Low | High |

| 12 | Pump Head | High | Low |

| 13 | Cleaning Frequency | More | Less |

| 14 | Tube Velocities | Low | High |

| 15 | HTC-Heat transfer co-efficient | High | Low |

| 16 | Representation |  |

|